Bodor M Series

Bodor M Series

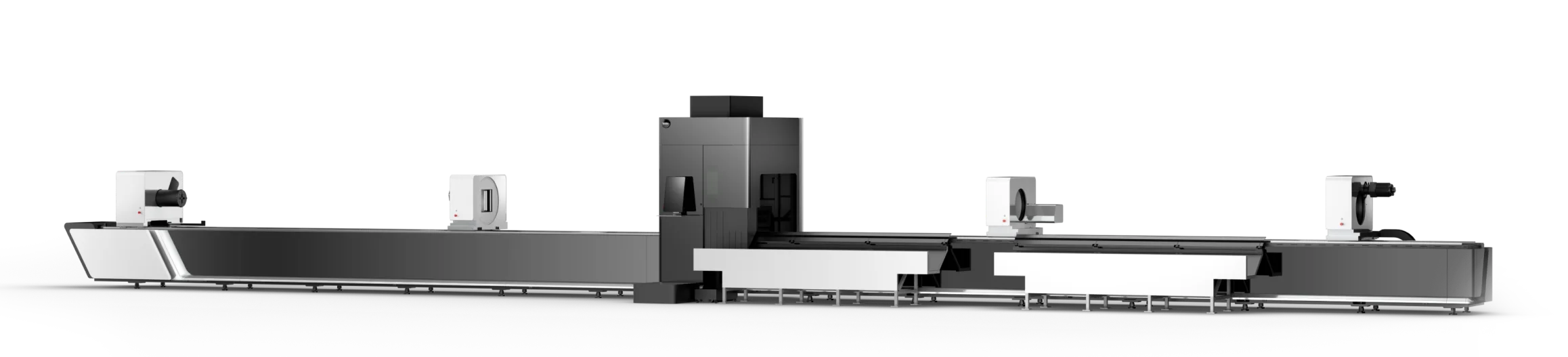

Bodor M Series Flagship Fiber Laser Metal Tube Cutting Machine

Enter the world of 4-chuck laser cutting

Extra large cutting range

The M series adopts a square-round structure chuck, which allows it to cut the maximum round tube diameter and the maximum square tube side length, providing users with more processing options.

0 Excess Material Processing, Waste Reduction

Minimize manufacturing waste from the source. During operations, M series will help you utilize every piece of material to the largest extent possible, reducing waste and improving cost-effectiveness.

Increased flexibility

The M series’s four chucks can be adapted to different processing scenarios. By intelligently switching between the heavy tube processsing and high-efficiency modes, the machine empowers you to tackle diverse cutting tasks with ease.

Edge collision prevention

When cutting rectangular or square tubes, the M series system calculates the tube’s corner rotation radius through the function, effectively preventing collisions between the laser head and the tube, and thus avoiding any damage to the laser head.

Servo-flipping unloading plate

The servomechanism of M series guarantees all machinery procedures work synchronously. The new servo-flipping plate has adaptive motions to facilitate the unloading process. While preventing redundant shaking or moving of the work piece, the plate is able to automatically categorize work pieces and remnant into different piles, thus lowering labor costs.

Airtight pneumatic chuck

Bodor’s airtight pneumatic chuck is intended to balance the act of high efficiency and low maintenance requirements. The 4-chuck mechanism of M series completes cutting in just 2 secs. Its airtight feature makes the chuck dust-resistant, meaning that dust cannot contaminate or cause any negative effects on regular chuck operations.

Tackling manufacturing waste

Bodor strives to be as efficient as possible at converting raw materials into products and reducing the amount of waste generated. This is the reason why M series is set to be waste-free in cutting operations. The extra 4th chuck of M series enables clamping at full, making sure that M series generates quality cuts even for the very last work piece. Without leaving leftovers, M series is able to effortlessly process a wide range of raw materials and profiles.

Excellent bevel cuts (optional)

The bevel cutting option of M series enables the production of high-precision bevel cuts in multiple degrees, optimizing subsequent assembly procedures and welding performance while lowering production costs.

Weld seam identification (optional)

With a simple camera set-up, M series can quickly detect weld seams on a variety shapes of tubes, even those located on the inside. This option is particularly applicable to manufacturers who would like to avoid weld seams during laser cutting.